Trauma of the hand, wrist and fingers is one of the more common injuries faced by workers in both developing and developed countries. For instance, the incidence rate of hand injuries reported for seven manufacturing environments around the world ranged from 4 to 11 per 100 workers per year. In the United States, workers with acute hand injuries account for over one million emergency department visits annually and are reported to be the most frequent body parts injured at work and treated in hospital emergency departments. One study conducted at a manufacturing site in Malaysia reported hand injury rates in the order of 30-40 % of workers per year.

This is obviously an important issue, and injuries to the hand can lead to long-term disabilities and greatly affect the well-being and productivity of workers, not to mention corporate bottom line. In this blog post I will explore this issue in some detail and provide an overview of types of the most common hand injuries, causes of injuries, and some of the important prevention measures to protect workers from these injuries.

Types and Causes of Acute Hand Injuries

Acute injuries are ones that arise from an injury and cause immediate trauma to the worker, e.g., a penetration wound or a laceration.

Sorock et al (2002) studied causes of acute hand injuries for workers in the US. In decreasing order of frequency, subjects were employed in machine trades, service work, structural work, and less frequently, in benchwork, professional, technical managerial and clerical, and sales work. The majority of subjects (83.4%) had a single type of injury: 62.6% were lacerations, 13.1% were crush injuries, 8.0% were avulsions (e.g.., tearing off of skin or fingers), and 6.1% were punctures. Metal items, such as nails, metal stock, and burrs accounted for 38.4% of the injuries, followed by hand tools with blades and powered machinery (24.4% and 12.3%, respectively).

The leading five conditions that contributed to an injury were:

- being in a hurry

- not realizing the hand was in a hazardous area

- misjudging time and distance to avoid an injury

- shifting work materials or tools

- attention not fully on task

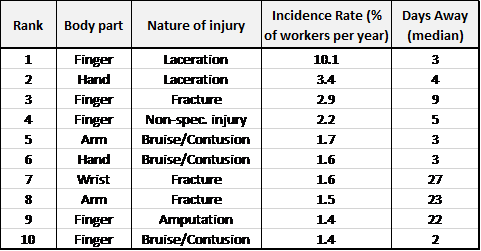

Courtney and Webster (1999) summarized US data from 1994 and ranked upper extremity traumatic injury cases with days-away-from work reported:

Given the high incidence rate coupled with the high number of lost work days to these injuries, this is a significant and serious issue.

For those readers interested in more details on this topic, I suggest you download and read the paper by Sorock et al (2002). They provide a very good review related to the incidences of hand injuries in various industries and discuss occupational and demographic factors.

Prevention of Acute Hand Injuries

Sorock et al (2002) state that the most common causes of hand injuries are associated with:

- carelessness

- lack of awareness

- boredom

- disregard for safety procedures

- distractions

And, to avoid hand injuries:

- know the hazards and dangers in the job to be done

- be aware of pinch points

- be aware of hot areas

- be aware of rotating or moving surfaces

- automated machinery may be controlled by remote control, or delayed timing devices that cause the machine to start automatically

- loose clothing and jewelry may be caught up in moving machinery

- never remove machine safeguards or operate machinery with safeguards removed

- follow the work practices and use the equipment and gloves provided by your employer

- be aware of the job tasks, equipment and materials that can create a risk for a hand injury or put your skin in contact with a chemical, and know the steps that should be taken to prevent exposures and injuries.

Types and Causes of Chronic Hand Injuries

Chronic hand injuries are ones that arise over a long period of time, from cumulative trauma resulting from long-term repetitive activities. Some of the most common types of chronic hand injuries include:

- tendonitis - inflammation of the tendons

- tenosynovitis - inflammation of the synovial sheath

- carpal tunnel syndrome - results when the median nerve is compressed, either from the swelling of tendons and sheaths or from repeated bending of the wrist

Such injuries can be caused by either too little movement or excessive movement while handling light as well as heavy loads. Often, repetitive strain injuries have multiple causes. For instance, a maintenance worker using a screwdriver may get pains from repetitive use of force while working at an uncomfortable angle. Office workers may sit in an uncomfortable position with no wrist support and use rapid finger movements on a poorly designed keyboard. In effect, any work that forces a person into an “unnatural” position can lead to repetitive strain injuries. The forceful twisting of a screwdriver, repetitive finger movements without rest, sitting in an uncomfortable position, bending the wrists for long periods, working with arms above shoulder length, gripping tools forcefully, etc., strain tendons, ligaments, and muscles causing injury.

For a simple presentation on acute hand injury prevention, I suggest you download this pdf file from NSC.

Prevention of Chronic Hand Injuries

The CCOHS website offers a good overview of causes and prevention of chronic hand injuries or work-related musculoskeletal disorders (WMCDs), and notes that prevention is best accomplished by eliminating hazards at the source.

In the case of WMSDs, the prime source of hazard is the repetitiveness of work. Other components of work such as the applied force, fixed body positions, and the pace of work are also contributing factors. Therefore, the main effort to protect workers from WMSDs should focus on avoiding repetitive patterns of work through job design which may include mechanization, job rotation, job enlargement and enrichment or teamwork. Where elimination of the repetitive patterns of work is not possible or practical, prevention strategies involving workplace layout, tool and equipment design, and work practices should be considered.

Job Design

- Mechanization - One way to eliminate repetitive tasks is to mechanize the job, where feasible or appropriate.

- Job Rotation -Job rotation requires workers to move between different tasks, at fixed or irregular periods of time. But it must be a rotation where workers do something completely different.

- Job Enlargement and Enrichment - increases the variety of tasks built into the job. It breaks the monotony of the job and avoids overloading one part of the body.

- Team Work - Team work can provide greater variety and more evenly distributed muscular work. The whole team is involved in the planning and allocation of the work. Each team member carries out a set of operations to complete the whole product, allowing the worker to alternate between tasks, hence, reducing the risk of WMSDs.

Workplace Design

- The guiding principle in workplace design is to fit the workplace to the worker.

- Evaluation of the workplace can identify the source or sources of WMSD.

- Proper design of the workstation decreases the effort required of the worker to maintain a working position.

- Ideally, the workstation should be fully adjustable, providing a worker with the options to work in standing, sitting or sitting-standing positions, as well as fitting the worker's body size and shape.

- For more information please check out a recent blog post on this topic by ergonomist Dr. Era Poddar - "One Office Doesn’t Fit All".

Tools and Equipment Design

- Proper design of tools and equipment significantly decreases the force needed to complete the task.

- Providing the worker with the proper jigs or fixtures for tasks that require holding elements saves a lot of muscular effort in awkward positions.

- Good tools, maintained carefully and where necessary frequently changed, can also save a lot of muscle strain.

Work Practices

- A well-designed job, supported by a well-designed workplace and proper tools, allows the worker to avoid unnecessary motion of the neck, shoulders and upper limbs..

- Training should be provided for workers who are involved in jobs that include repetitive tasks.

- Workers need to know how to adjust workstations to fit the tasks and their individual needs.

- Training should also emphasize the importance of rest periods and teach how to take advantage of short periods of time between tasks to relax the muscles, and how to consciously control muscle tension throughout the whole work shift.

- Increased communication and support together with an increased ability of the worker to control his job (where possible) are work practices that improve worker’s satisfaction and have a positive impact on reducing the risk of WMSDs.

I have only touched upon the proverbial "tip of the iceberg" in my discussion of hand injuries in this blog post. Check out some of the referenced provided above for more details. But most importantly, be aware that this is a serious (and often overlooked area), understand the risk areas and practices at your facility, and do what you can to minimize these risk to your workers. In other words give your workers a (safe) helping hand!

I thank a reader of my blog, M.U.K. from Pakistan for suggesting this topic.

We hope that you will bookmark the blog, share it with your colleagues and visit the blog frequently because you find it informative and helpful. We value your feedback and suggestions for future topics.

Please enter your email in the box at the top of the post and subscribe to our blog HSE Asia - our weekly blog will be emailed directly to you.

Next Week’s Blog Topic: Do We Really Need an HSE Legal Register?

Photo Credits: Hand image courtesy of Rachel Gilmore at www.freemimages.com.

- Is Your Business Compliant with HSE Regulations? Take Our Quiz to Find Out! - September 16, 2024

- Duty of Care: What it Is and What it Means to Companies Operating in the GCC? - January 28, 2024

- Free E-Book:Health, Safety, and Environment Regulatory Review – United Arab Emirates: An Overview of Federal Requirements - July 5, 2023